If you have, like me, been in Silicon Valley long enough – or even just followed the tech news – you have been through your share of hype cycles.

Remember the early dot com craziness? The idea that our lives would completely happen online and nobody would ever try to find a romantic partner at a party or buy stuff at a store anymore because we had wonderful online offerings like match.com and socks.com? We pretty much got there – whether we like it or not – only 20 years later.

Then there was blockchain, cryptocurrencies, crowdsourcing and so many more.

Now we are in another mother of all hype cycles: the generative AI or gen AI hype cycle.

Don’t get me wrong, gen AI is fantastic, I ask it grammar questions all the time, I recently had it write a haiku and structure a business plan for me. If I was coding, I’d use it for that. I even worked on augmenting an LLM to create a wonderful tool: the world’s first model that can answer all your questions about carbon dioxide removal from the atmosphere (check it out here).

The fact that gen AI has useful applications and that over time there will be many more useful applications doesn’t mean that we aren’t in a major hype cycle. It sort of feels like dot com circa early 2001.

One area I am following closely is the gen AI hype cycle in manufacturing and there it is causing some havoc.

Trying to run before you walk

“Don’t run before you walk” is a somewhat overused phrase but accurately describes the situation. It was only yesterday that most manufacturers didn’t really know what artificial intelligence is and could potentially do for them. From there we went seemingly over night to the executive mandate “go do ‘something’ with gen AI”.

Here is the issue with that: not all AI is gen AI, in fact, the AI best suited for applications on the shopfloor is so called classical or mature AI. Here is how they differ and why this why this difference matters.

“Classical AI”, specifically machine learning (ML) has been around for longer than most people realize: the first models were developed in the fifties. In the early aughts I saw the first attempts of using them to find patterns in biological data. These were early efforts hampered by model quality and computing power. Initial versions of the models that now do their job in literally a split-second crunched data for days before crashing on the finish line.

ML models have done a lot of maturing over the last 10 years and can by now be called mature or even classical. We know they work if properly trained with enough high-quality, clean data and they do not hallucinate. There are tools available that help users understand how and why the algorithm came up with a specific answer.

Classical AI is by now almost deterministic: the outcomes are fully determined by the initial inputs with no randomness or unpredictability involved. With classical AI, the same set of inputs will produce the same outputs.

Let’s not forget computing power: it’s now sufficient to run these models very quickly.

Classical AI has a lot of very convincing use cases in manufacturing. Take visual inspection: there is currently no good solution for it. Humans are slow, expensive and make lots of mistakes, automated legacy vision systems on the other hand are still expensive, inflexible and while they work well under optimal conditions, they fail when things aren’t just so (think dimmer light because a light bulb blew, or somebody knocking the camera slightly out of alignment).

Enter classical AI. When trained with enough sample images AI can detect defects and categorize them 24/7 using cheap cameras with more than 99.99% accuracy even if the light gets dimmer and the product isn’t smack in the middle of the frame – and it can do this once every 40 milliseconds. This is a perfect and solid application of classical AI: it fixes a real, unsolved problem.

Is it an easy overnight implementation? Certainly not, but doable in a reasonable period of time (a few weeks for a proof-of-concept) and with proven business value and returns.

Given these characteristics deploying classical AI should be high on the list of every manufacturer looking for innovations that help the bottom line.

Suddenly Gen AI

But along comes gen AI with its flashy claims and immediate appeal to anybody who writes anything (everybody) and the classical AI is all but forgotten before it could ever prove its usefulness.

Suddenly attitude towards AI shifts from the exploratory “let’s see whether this AI thing is useful to us” to a corporate mandate “let’s do something with gen AI!”.

However, actual use cases for gen AI on the shopfloor are hard to find and harder to prove out because of its challenges, specifically its penchant for making things up and hallucinating.

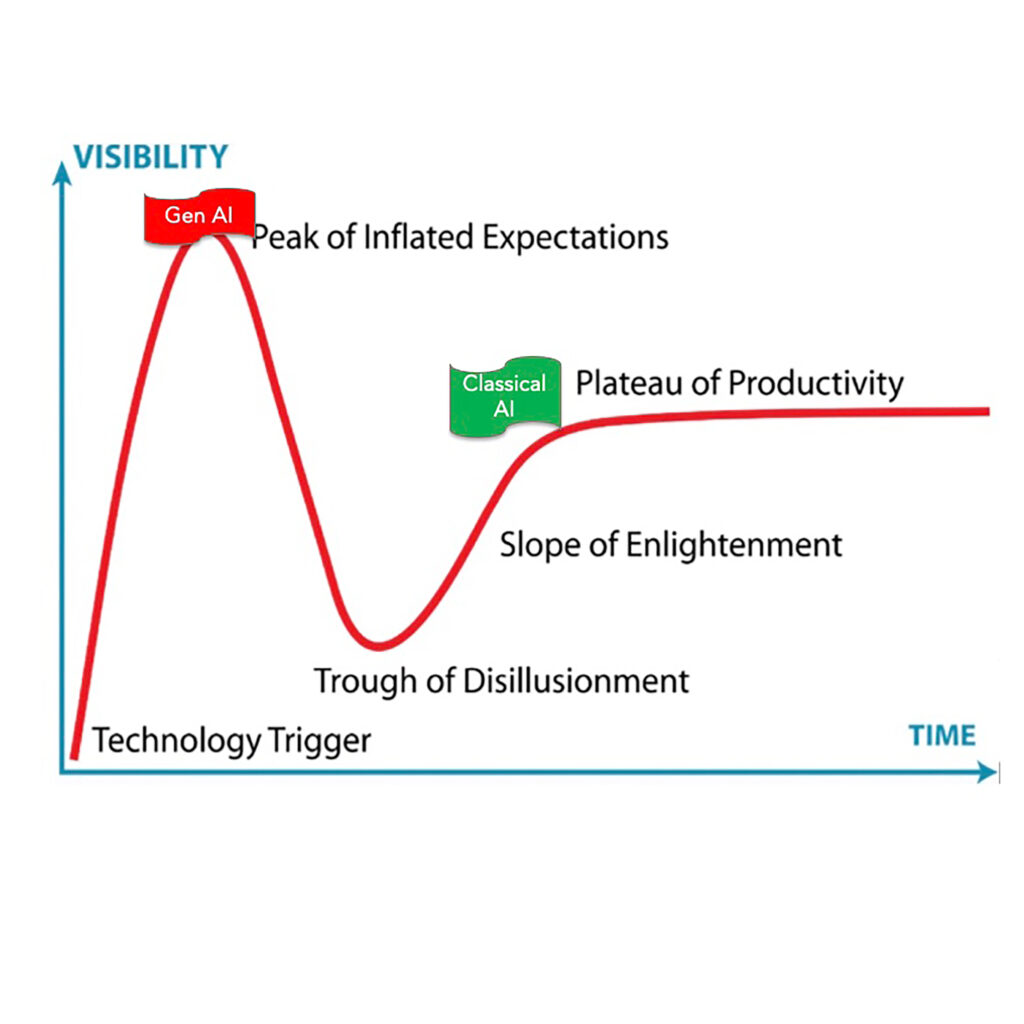

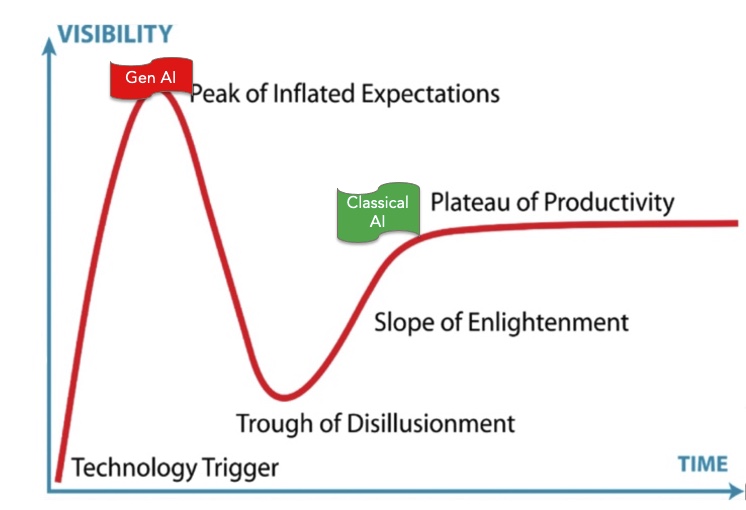

Will we get there? Sure, eventually, but right now there are many exciting use cases for gen AI but visual inspection or predictive maintenance aren’t among them. But what happens is that gen AI is speeding up that steep initial Gartner hype cycle incline reaching the peak of inflated expectations very quickly (right about now the sentiment seems to be tipping) and is headed towards the trough of disillusionment – classical AI in tow.

Getting off the Gen AI Hype Cycle

Manufacturers, frankly, currently have no business implementing gen AI for shopfloor operations unless they are already high up the classical AI learning curve. The best approach is to let the value of gen AI work itself out over the next years without risking product quality, profitability and employee safety.

While waiting for the gen AI “killer apps” for shopfloor operations to emerge, classical AI is here and ready to prove its value. The frantic “let’s do something with gen AI” mandates are destined to fail, but from our own experience we know that carefully planned and executed classical AI deployments save cost in manufacturing every single day. It might be because scrap is reduced, changeover cost are lower, line speed can be increased or customers are happier – or a combination of these factors – but we see tangible results.

So, our advice to manufacturers is to get off the accelerated gen AI hype cycle. Let’s go back to classical AI where we are sitting right where we should be: at the corner of where the slope of enlightenment turns into the plateau of productivity.

Let’s return to what manufacturers do best, use reliable tools to meticulously engineer cost out of processes while making them better in a methodical and planned fashion.

Meanwhile, gen AI really does write decent haikus.

P.S. There is use case for gen AI in manufacturing. We wrote about it here.