Consumer Packaged Goods (CPG) manufacturers deal with a challenging set of demands and constraints related to quality inspection: they operate very high-speed lines with cycle times in the tens or hundreds of milliseconds and they are under constant pressure to reduce cost. Can AI help CPG manufacturers address these issues?

CPG Quality inspection now

Currently, quality inspection is typically done in one of two ways. The manufacturers deploy either:

- machine vision systems or

- employees who check a small number of samples for defects

The challenge with machine vision is that it has the potential to slow down production. Most production lines could go faster, but image analysis just can’t keep up. Machine vision is also expensive because it requires high-quality, costly camera systems. Even when one has the funds to implement it, machine vision cause cause problems because it is finicky; for example, it is very sensitive to changes in the environment such as the lighting conditions in the plant over the course of the day. Even small changes in the camera system’s position e.g., somebody bumping into it, creates issues with defect detection.

Testing of a limited number of samples is a manual process and therefore slow and expensive. It also comes with the risk of not noticing quality problems quickly so some defective products might have already been shipped to the customer and root cause analysis as well as fixing the quality issue are delayed. Scaling up the inspection rate, however, quickly becomes prohibitively expensive and increasingly hard to hire for and is therefore not a viable alternative.

AI for CPG manufacturers

In an ideal world, CPG manufacturers could affordably inspect each product and not just establish whether the product is OK or defective (NOK), but also categorize defects for root cause analysis which will help to avoid these defects down the road.

Deploying artificial intelligence in quality inspection makes it possible to improve all three of the important parameters – high speed, low cost, and 100% inspection – simultaneously.

What our CPG customers say

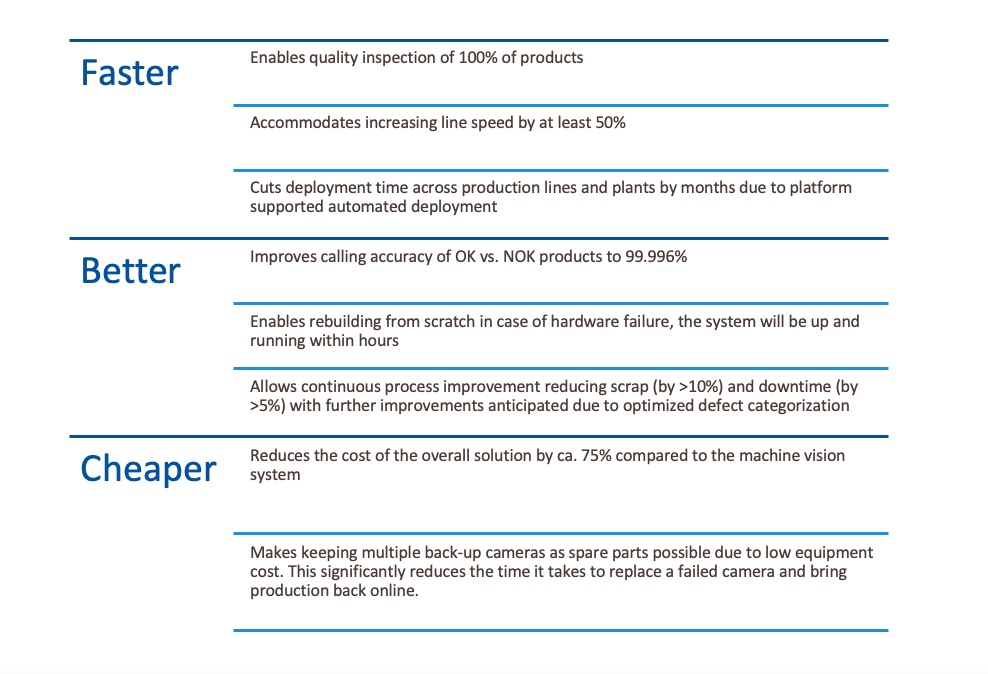

At Accella AI we custom-built an AI solution for CPG manufacturers, the Accella Quality Box™ that enables them to meet the challenging triple goals of faster, better, cheaper.

We have worked with a number of manufacturers in the CPG industry and deployed our AI Bot to enable high-speed inspection and defect categorization of every product while lowering cost.

Here is an overview of some of the improvements and savings one of our CPF customers has realized.

If you are curious about how to use AI for your own manufacturing plan, contact us to have a chat.

If you’d like to read more about transitioning your company to AI-based QC and Industry 4.0, you can read our article about Transitioning Manufacturing to Industry 4.0 – Perspective from the Shopfloor