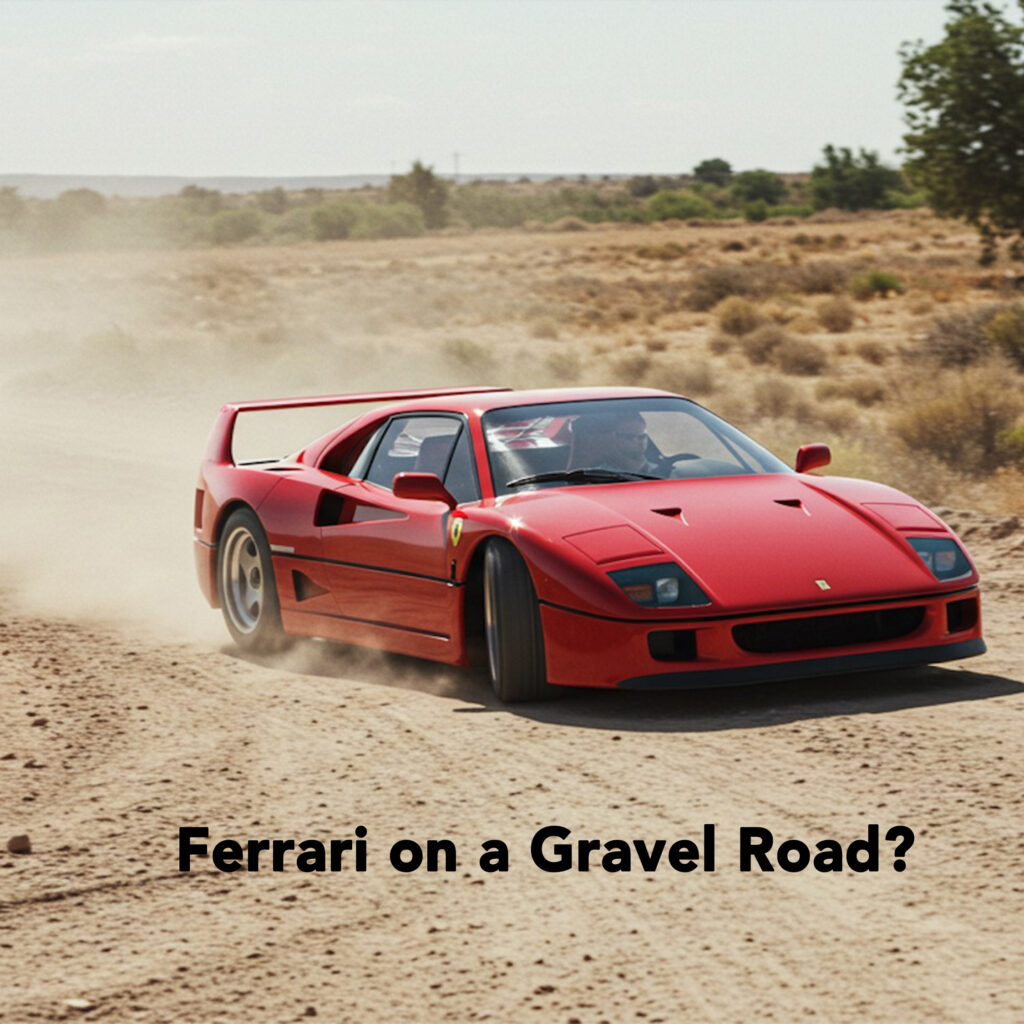

Ever dreamt of driving a Ferrari? If so, you probably saw yourself flying down a German Autobahn during an important soccer match – empty lanes, no speed limit. What your dream didn’t involve was driving that high-performance machine on a gravel road, carefully inching forward to avoid damage and never experiencing the thrill of really pushing it.

Is deploying artificial intelligence on the manufacturing shop floor like driving a Ferrari on a gravel road?

AI promises game-changing efficiency and improvements, but is it too advanced for the manufacturing shop floor today? Does the lack of infrastructure, data quality and digital readiness make it impossible to take full advantage of all AI has to offer?

In this blog, I’ll argue that the road might not always be as smooth as a newly paved Autobahn but that whatever obstacles there are can be overcome with the right tools and approach.

Is There Gravel on the Road?

Sure, there is. In my six years of working with manufactures on AI implementations I never walked into a situation that looked like an Autobahn; you get a decent two-way country road on a good day.

The “gravel” we encounter is pretty consistent: the clean, structured data needed for AI is not available, legacy infrastructure makes things complicated, there are challenges around workforce readiness, and uncertainty about the return on investment.

All of these obstacles are serious but, as our work with several manufacturers has shown, do not have to be an AI show stopper.

The Reality Check: Why These Barriers Aren’t Insurmountable

The first thing to keep in mind is that incremental adoption is the way to go. AI doesn’t need a full digital transformation overnight; targeted, small-scale implementations are generally enough to showcase the value of AI on the shop floor. In our experience visual inspection is a good place to start, even if you don’t have enough data, as long as you manufacture at a reasonable throughput the necessary data can be generated in a relatively short period of time. This buys time to proactively prepare tackling data readiness for larger implementations.

Issues with legacy systems – in our experience – are manageable. Legacy production equipment is not a problem, as long as the data generated can be accessed. In case of visual inspection, one or more newly placed cameras will generate the data needed fairly quickly. Sensors, IoT devices, and middleware solutions can retrofit older machines for AI-readiness. Your AI solution provider should be able to connect to all standard PLCs.

Workforce readiness is often the toughest nut to crack. Here – again – it helps to start at a measured pace: a straightforward application allows the organization to get familiar with deployments of AI on the shop floor, learning-by-doing brings people up the learning curve and gives them the chance to become part of the transformation rather than just being onlookers.

Two things are important here:

- First, select a vendor that has a myopic focus on user-friendliness. Whatever AI solution you deploy, you want your people on the shop floor to be able to handle and maintain and eventually deploy it. This gives you more control and saves a good deal of money compared to your vendor or a newly hired data scientist (who typically won’t know manufacturing from accounting) doing all the work.

- Second, you need a champion on the shop floor. An executive mandate along the lines of “we have to do something with AI” might get the ball rolling, but to successfully complete a proof-of-concept and later the implementation you need the help and expertise of people who are on the shop floor every day and are supportive, or better yet, enthusiastic about the opportunity to adopt the latest technology.

Paving the Road: How to Prepare for AI on the Shop Floor

So, while deploying AI on your shop floor might come with challenges, they are nothing like turning a gravel road into an Autobahn to drive that Ferrari. The critical steps are:

- Start small and scale smart – Focus on a single use case with high potential impact that is relatively fast to implement and doesn’t require months of cleansing data before you get started. Visual inspection is often a good first project for a quick win.

- Invest in data infrastructure – Implement systems to collect, clean, and standardize data before you need them. This is often a stretch goal for companies but it is a good goal to have and to get started working on the sooner the better.

- Ensure human-AI collaboration – AI on the shop floor should augment workers, not replace them; this is an important point to communicate upfront to the shop floor team. Make your existing personnel part of the journey to lower resistance (and there will be resistance).

- Work with the right partners – Select a vendor who understands the industry and the realities of the manufacturing shop floor. Years of experience have taught me that training a model is not the hard part, the hard part is building the necessary integration to MES, talking to the PLCs, setting up a system that tolerates dust, heat, splatter or whatever other challenging conditions there might be and – importantly – can be operated by technicians and engineers. You need a partner who speaks your language, not a geek squad.

- Make the business case – it might be difficult but important to get past the point of “we could save some time using AI” and really explore the economics of an use case. In my experience generally you will find that the economics work out strongly in favor of AI on the shop floor.

Driving that Ferrari

Currently, AI on the shop floor is still a choice that is adopted by only a few forward-thinking manufacturers. This will change and instead of eking out a competitive advantage, manufactures will need to adopt AI to keep up or make up for lost time.

There is gravel on that road to adoption, from small pebbles to sizable boulders but nothing that can’t be overcome. What matters is to get on the road, make slow progress on that country road and finally get to the Autobahn where you can really drive that Ferrari.

Thanks to Stefan Obert for the metaphor of driving a Ferrari on a gravel road. Credit where credit is due!