Visual inspection is a “killer app” for AI. There are many reasons why we keep saying that: AI is fast, works 27/7 without tiring, is highly accurate and generally pays for itself within a matter of months. However, there is another reason why manufacturers should take a very serious look at AI: it allows for standardization in visual inspection.

In this blog we discuss the importance of standardization, especially for visual quality inspection, and the critical role AI can play in achieving standardization compared to traditional methods of visual quality inspection.

Standardization in Manufacturing – Why It Matters

Standardization in manufacturing is more than a nice-to-have, it is crucial because it ensures consistency, efficiency, and – where applicable – supports regulatory compliance. All of these are essential for maintaining high manufacturing standards and operational reliability.

- Consistency: Standardization minimizes variability across production processes, ensuring uniform execution of tasks across shifts, production lines, and facilities. This leads to predictable outcomes, stable operations, and reduced inconsistencies in manufacturing workflows

- Efficiency: AI-driven standardization streamlines shopfloor operations by optimizing workflows, reducing manual interventions, and enhancing process reliability. This results in higher throughput, lower operational costs, and minimized downtime, ultimately improving overall productivity.

- Regulatory Compliance: Many manufacturing sectors must adhere to strict safety, environmental and operational regulations. Standardized processes help ensure compliance by maintaining accurate, traceable, and auditable records, reducing the risk of non-compliance penalties.

Standardization is critical for many manufacturing tasks: standardizing workflows can increase assembly line efficiency by reducing errors and speeding up production, standardized equipment maintenance helps prevent unplanned downtime and standardizing processes reduces variability in machine settings resulting in less rework and scrap.

Visual inspection is arguably one of the most critical areas to standardize so, as a manufacturer, you can be sure that all products meet the same quality standards and variability in defect detection is kept to a minimum.

AI’s Superpower: Standardization in Visual Inspection

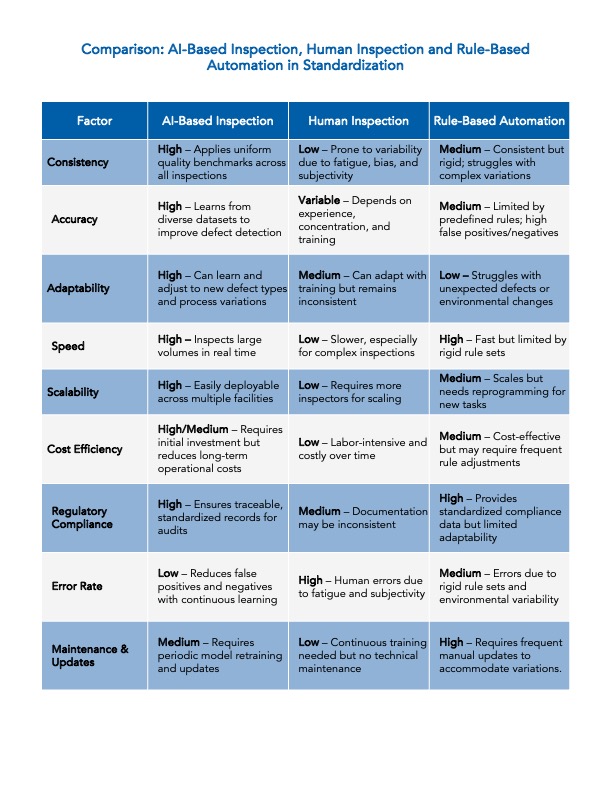

There are three main ways to perform quality inspection: the conventional methods of human inspection and rule-based automation and – more recently – AI-driven inspection. For visual quality inspection and standardization of this process the conventional methods both have serious short-comings compared to AI-based solutions.

- Human inspection is prone to variability because inspectors tire, might have cognitive biases or make subjective judgments. Over time and across different shifts, there is a chance that inspectors interpret defects differently which leads to inconsistencies in quality control. As a result, defective products might end up being shipped to customers or good products getting rejected, both increasing cost and reducing efficiency. Also, customers might receive products of different quality because of the inconsistencies in quality control.

- Rule-based automation systems have been used to achieve some standardization in visual inspection. While they generally perform better than humans, they, too, come with significant limitations. These systems rely on predefined parameters and rigid algorithms and therefore lack the ability to adapt to variations in product appearance, external conditions, or subtle defects. A high rate of false positives and negatives is the result which makes them suboptimal for handling modern manufacturing complexities.

- AI-based systems address the short-comings of both these traditional approaches: they detect defects with high-accuracy even in sub-optimal circumstances – think challenging lighting conditions – are adaptive and apply consistent criteria across all inspections. This minimizes variability, reduces errors, and makes sure the quality standards are uniform.

How AI Enables Standardization in Visual Inspection

AI is uniquely suited for standardizing visual inspection because of how it works, specifically:

- AI models learn to identify defects similar to how humans learn, by seeing many examples during training. By training them on diverse datasets from a wide range of real-world variations in product appearance, defect types, and manufacturing conditions they can establish uniform quality benchmarks and apply them consistently. AI can quickly process thousands of labeled defect images and by analyzing data from multiple production lines and facilities, it ensures consistent quality standards across different locations, materials, and manufacturing conditions.

- Machine learning enables objective and repeatable defect detection by eliminating human bias and inconsistencies. Once AI has been trained to recognize a defect it can identify it with precision and ensures uniform quality control across shifts, production lines and facilities

- In addition, AI continues to learn and improve as it sees more data e.g., more images of defects, over time which helps it to adapt to new patters and reduce false positives and false negatives.

Table 1 shows a comparison of AI-based visual inspection with human inspection and rule-based automation.

Standardization Another Reason to Adopt AI on the Shopfloor

We are only at the beginning of the AI journey in manufacturing but already AI-based solutions convey tangible and compelling competitive advantages to manufacturers, especially in quality inspection. As a company specialized on developing and implementing these solutions, we are seeing more and more interest by forward-thinking manufacturing professionals who are interested in exploring the capabilities of AI in their own plants. In addition to accuracy, robustness, speed, cost efficiency and reliability, standardization is a compelling benefit that sets AI-based solutions apart from conventional methods.

To see for yourself, consider a pilot program or consultation. We are happy to talk and identify use cases that will have a real impact in your plants.

For more information about AI in visual inspection please check out our Blog “Seeing is Believing: How AI is Changing Visual Inspection for Good

This blog addresses some of the most frequently mentioned challenges – and how real or not they are in our experience: Challenges of AI in Manufacturing – the Perspective of an Implementation Professional

Contact us here