Artificial intelligence (AI) will transform manufacturing – it’s just a matter of time. While few manufacturers have broadly adopted AI on the shop floor yet, the advantages of AI for applications such as visual inspection and predictive maintenance are just too convincing to ignore.

One of the biggest road blocks to AI adoption is fear of AI, the notion that “AI will take over” and humans will be sidelined. However, on the manufacturing shop floor this fear is much less relevant than in other fields; even as AI automates and enhances processes, the role of humans is and will remain essential.

The ideal scenario is a balanced partnership between human and machine intelligence which will maximize the value manufacturers can derive from both: humans and machines.

In this blog we explore what AI does exceptionally well, why humans are indispensable in AI-enabled manufacturing and highlight how the synergistic relationship between people and technology is crucial to success.

Speed and Consistency: Strengths of AI in Manufacturing

There are two main areas we will focus on that clearly showcases the relative strengths and weaknesses of humans and AI.

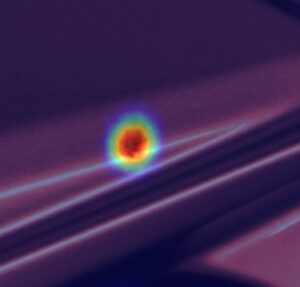

Processing Visual Information – AI is truly a powerhouse when it comes to handling certain tasks in visual inspection that humans are traditionally not very good at: repetitive, high-volume tasks such as detecting product defects quickly, reliably, without tiering or losing focus and at very high speed. Equipped with modern camera systems AI can even detect very small defects that the human eye is unable to see.

An example from our experience is the detection of sub-millimeter defects on reflective class A surfaces of expensive aftermarket car rims. AI can also learn to identify new types of defects, and to categorize defects which supports root cause analysis.

Pattern Recognition – Pattern recognition in huge data sets is another core strength of AI. This is where AI shines: it excels at processing speed and can crunch through very large data volumes in seconds.

This blazing fast processing speed and ability to deal with big data is extremely useful for applications like predictive maintenance where large amount of disparate data need to be analyzed to discern patterns, correlate them to outcomes, e.g. equipment failure, and then learn to spot those patterns early so that in the future equipment can be serviced before it breaks down.

Therefore, AI can and will automate tasks that are currently at least partially performed by humans. However, these highly repetitive tasks are very hard for humans to perform well, are boring and generally unpopular, hard to hire for and experience high turnover. AI can also process and analyze massive datasets in real-time to inform decisions about maintenance schedules boosting productivity. In the process, AI can free up humans to perform more value-added tasks.

Human Strengths on the Shop Floor

So, what are these value-added tasks, that humans excel at?

Humans are masters at intuitive pattern recognition and are able to leverage their cognitive abilities and prior experiences to interpret complex scenarios. They outperform AI when it comes to tasks like:

Contextual understanding – humans grasp the broader context of a problem. For example, a human inspector might be needed to determine whether a product defect affects usability or is merely cosmetic and how this defect affects customer satisfaction.

Strategic Oversight – human decision-makers are needed to ensure that AI outputs align with organizational goals and values. For example, while AI can recommend cost-saving measures, humans weigh these recommendations against long-term consequences, such as environmental sustainability or workforce impact.

Continuous Improvement – humans are essential for refining AI systems by providing feedback, adjusting algorithms, and identifying gaps in performance. This iterative process improves AI’s accuracy and adaptability over time.

Creativity and problem-solving – humans are able to use their creativity to come up with innovative solutions to challenges, even if they have never encountered that specific challenge before.

Imperfect information – humans can make decisions even in situations where they have imperfect, limited information while classical AI struggles with scenarios it hasn’t been explicitly trained for. A predictive maintenance algorithm, for example, might not be able to make good decisions in corner cases, such as combined machinery failures or environmental factors, while humans are able to decide on a course of action.

Ethical oversight and ensuring compliance – humans can make decisions based on ethical considerations, empathy, and fairness, something AI cannot do. Humans are therefore needed to interpret AI-driven insights and ensure alignment with overarching business strategies.

These human superpowers reinforce that humans need to continue to play an active role in AI-enabled manufacturing.

A Balanced Approach: Collaborative Intelligence

The winning strategy therefore is to leverage what humans and AI each do best and use a balanced approach to integrate AI where and when it complements human capabilities. For example, letting AI handle repetitive and time-consuming tasks allows engineers and technicians to focus on more complex problem-solving and decision-making challenges leading to more efficient and effective quality control, where AI handles routine inspections, while human experts address intricate issues that require nuanced judgment.

In predictive maintenance keeping humans in the loop is also critical. Technicians and engineers are needed to interpret AI predictions, validate findings, and execute maintenance activities. Their domain knowledge and practical experience are essential in understanding the context of AI-generated alerts and deciding what to do.

Another crucial aspect is, that AI cannot train itself, human oversight is needed to properly train algorithms and make informed decisions based on AI- generated insights.

The important lesson learned for manufacturers is that the future lies in the collaboration between humans and AI and ensuring that both are deployed in a way that they augment each other, rather than compete.

Find more information about how AI is changing manufacturing for good here and look through our use cases.

Questions? Contact us